CP Extrusion color mixing and dosing

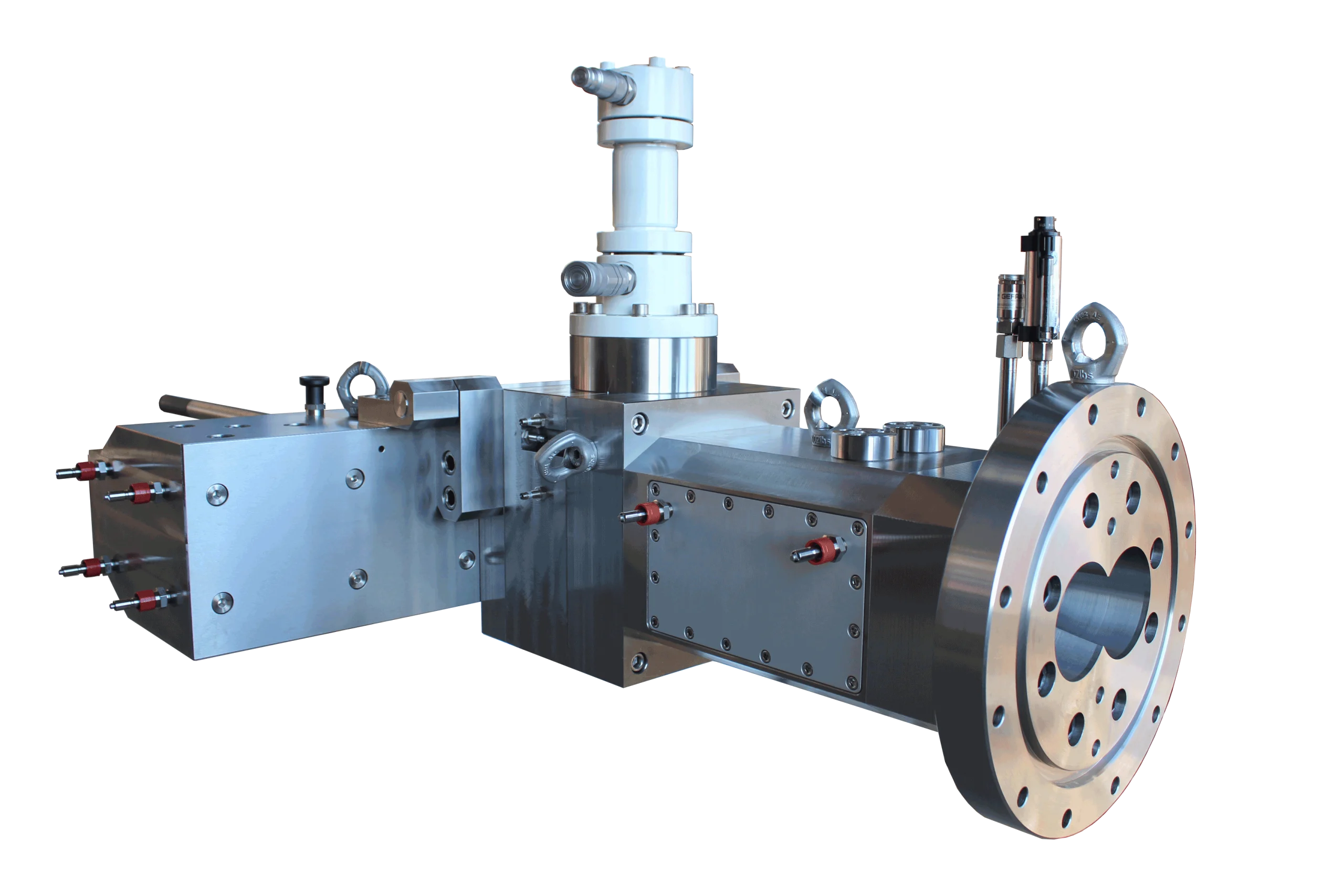

X-mixer:

CP Extrusion can make your product multicolored or multiflavored with the use of only one extruder. A specially designed mixing head, called “Cross mixer” (X-mixer), is fitted on the extruder including color and flavor injectors.

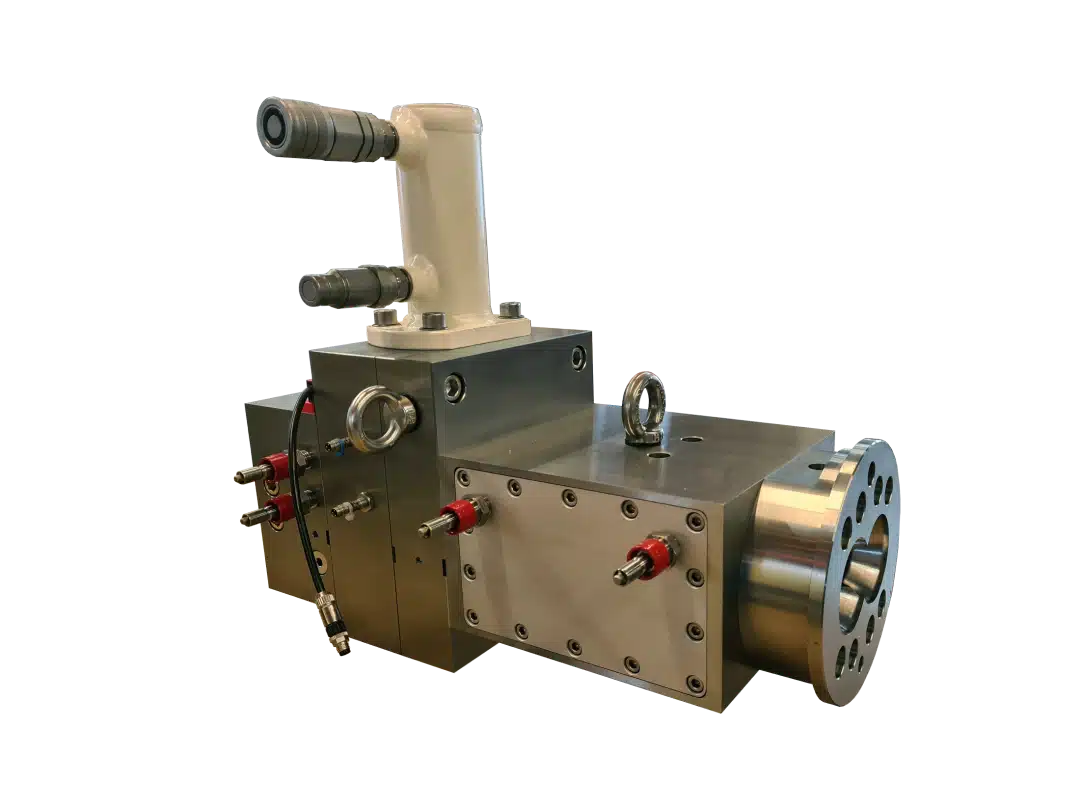

I-mixer:

Another option to add two different colors into the mass is the use of an “Integrated mixer” (I-mixer). This device mixes the additives into the mass without the help of an external drive.

The amount of colors can vary. The main stream out of the extruder is divided correspondently the required amount of colors and / or flavors. Special mixing devices are installed to ensure a homogeneous mixing of color and flavor into the mass. In the following die the streams come together to make multicolored products or multiple products of various colors. It is even possible to switch colors within one single strand.

Main advantages of the X-mixer and I-mixer are:

CP Extrusion can make your product multicolored or multiflavored with the use of only one extruder. A specially designed mixing head, called “Cross mixer” (X-mixer), is fitted on the extruder including color and flavor injectors.

I-mixer:

Another option to add two different colors into the mass is the use of an “Integrated mixer” (I-mixer). This device mixes the additives into the mass without the help of an external drive.

The amount of colors can vary. The main stream out of the extruder is divided correspondently the required amount of colors and / or flavors. Special mixing devices are installed to ensure a homogeneous mixing of color and flavor into the mass. In the following die the streams come together to make multicolored products or multiple products of various colors. It is even possible to switch colors within one single strand.

Main advantages of the X-mixer and I-mixer are:

- Multi colored and / or flavored products out of a single neutral mass. (Only one extruder needed!)

- Compact design which can easily be mounted on your present extruder

- Can be used for different mass types

- Easy accessible for maintenance purposes

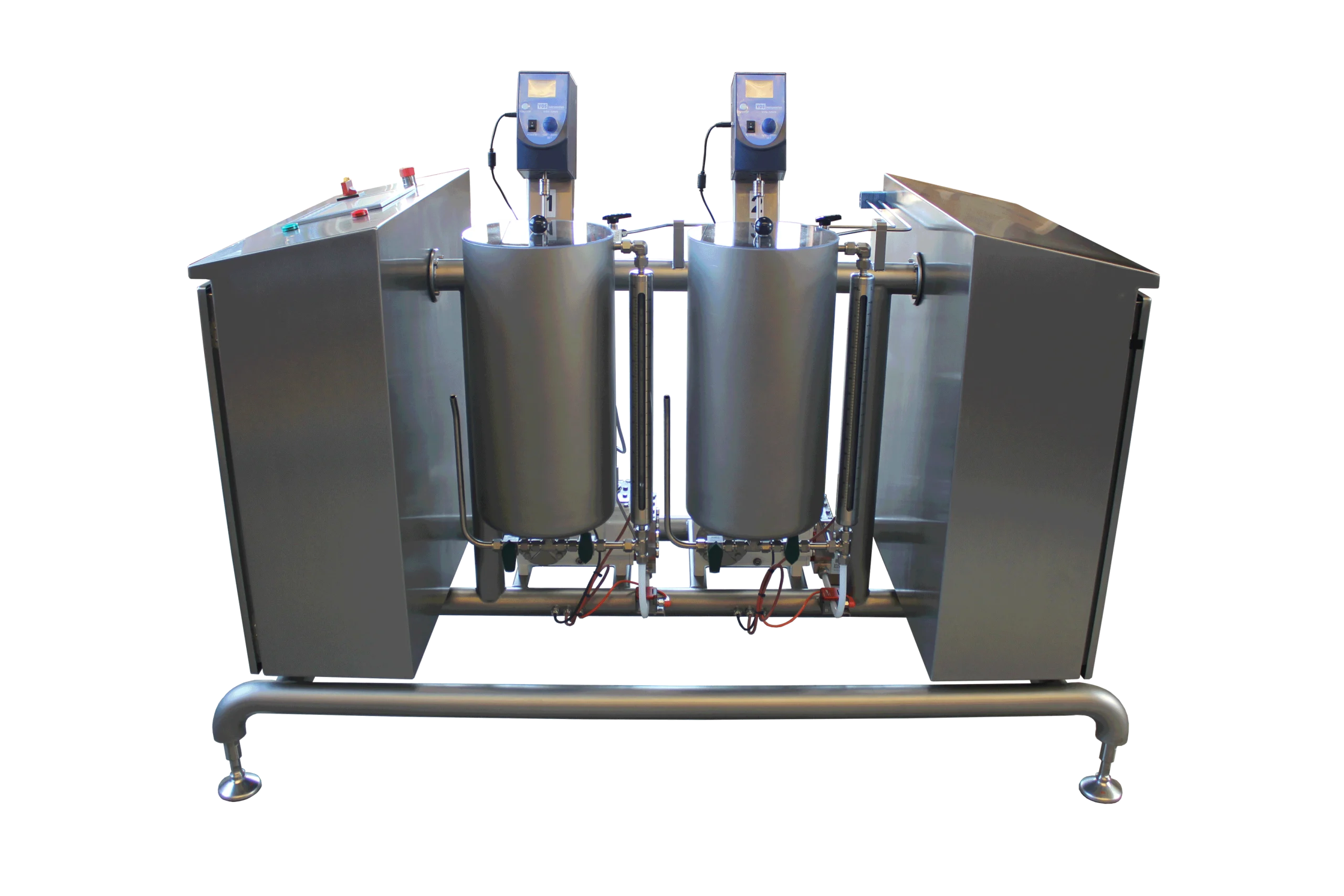

Dosing

For the injection of color, flavor or other additives into the extruder, X-mixer or I-mixer we deliver complete dosing skids. Our dosing system will be custom made. Depending on your requirements the system can be executed as:

● Stationary or movable (can be used on other places in you production facility)

● Manually adjusted or fully automatic (flow rate will follow extruder throughput)

● Manually cleaned or CIP (less labor intensive)

● Physical flow measurement, with flow meters or “lost in weight”. ( the last two options will prevent product loss due to undetected malfunction of the dosing system.)

Reliability and accuracy are extremely important for a consistent product! We acknowledge the importance of a thorough dosing and mixing system. Please find out how to improve you product consistency by contacting us.

● Stationary or movable (can be used on other places in you production facility)

● Manually adjusted or fully automatic (flow rate will follow extruder throughput)

● Manually cleaned or CIP (less labor intensive)

● Physical flow measurement, with flow meters or “lost in weight”. ( the last two options will prevent product loss due to undetected malfunction of the dosing system.)

Reliability and accuracy are extremely important for a consistent product! We acknowledge the importance of a thorough dosing and mixing system. Please find out how to improve you product consistency by contacting us.