Extruders

CP Extrusion extruders for the confectionery industry can be divided into three main categories. Read more about this down below

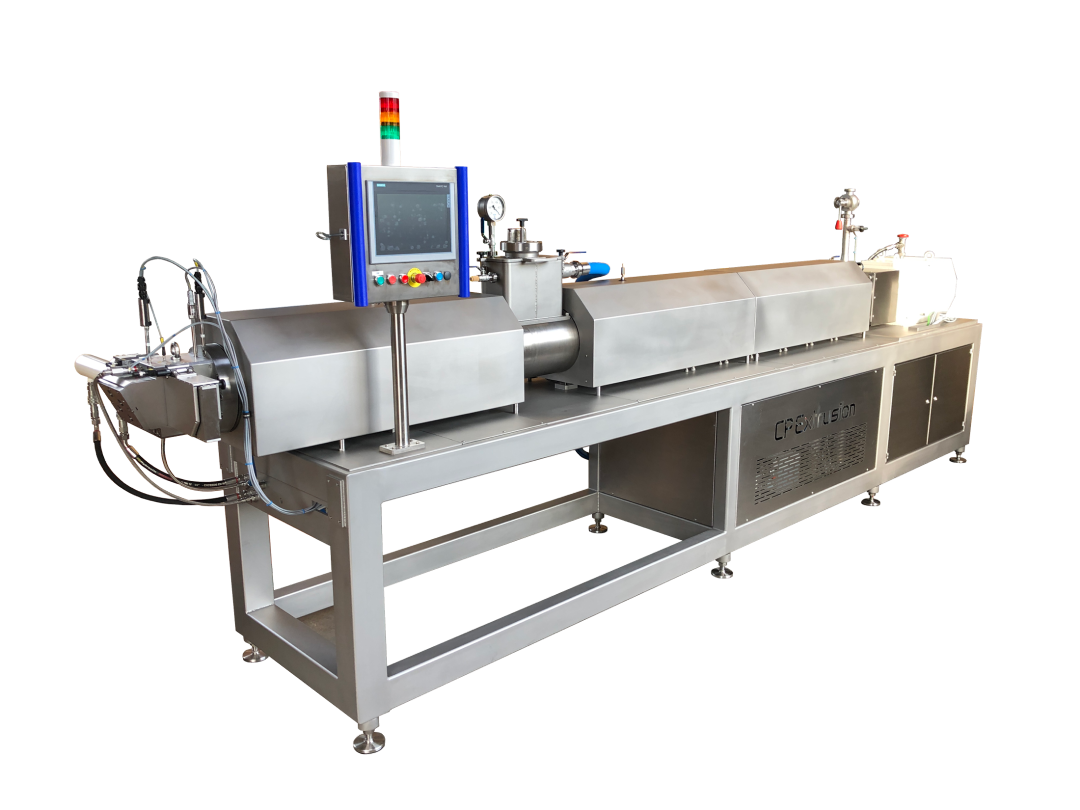

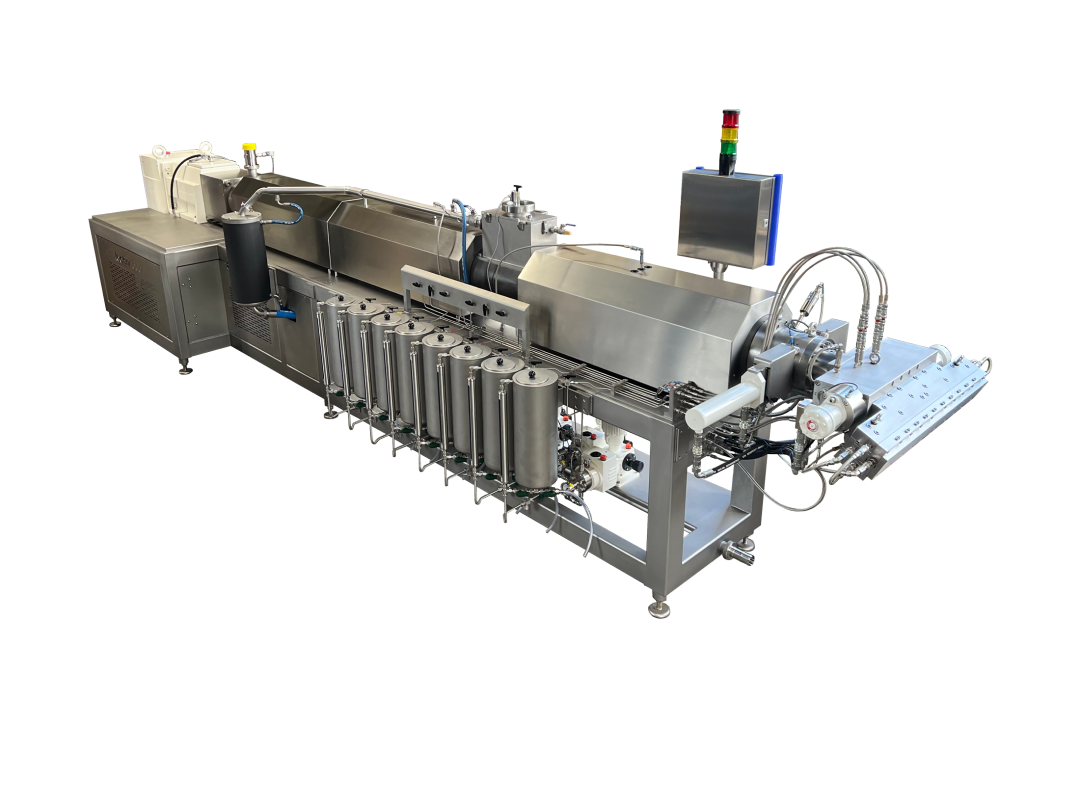

Cooking extruders

This modern twin screw, counter rotating, intermeshing extruder is mainly used for the production of Licorice. Due to it’s revolutionary screw design we’ve managed to obtain a much lower (- 30%) energy consumption compared to other suppliers.

In one single machine the mass is cooked, mixed, dehumidified and pressed though the die-system. This results in the following advantages:

- Constant and controllable cooking temperature

- Constant throughput

- Low and constant moisture content of product

- Minimum waste during start up and stop procedure

- Quick changeover times to other recipes and products

- Self cleaning

- Economic due to low labor costs and energy consumption

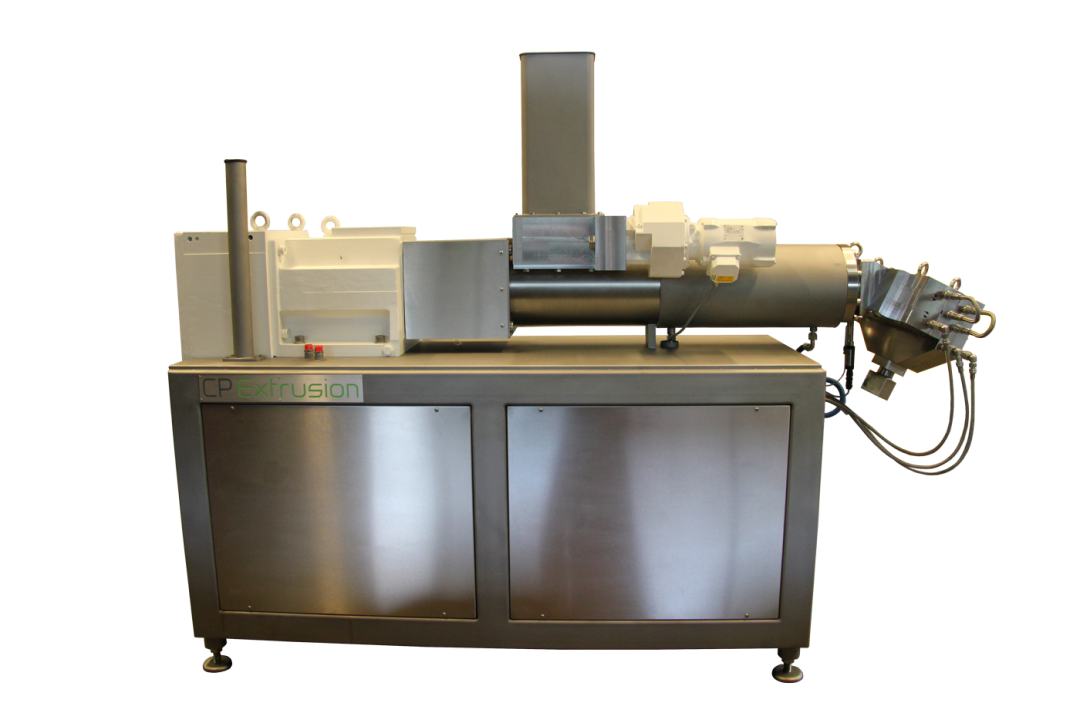

Mixing extruders

This twin screw, co-rotating, intermeshing extruder is used for several purposes:

Due to it’s excellent mixing properties it’s often used for mixing further ingredients, such as color, flavor or acids into a certain mass. (Licorice, sugar paste, chewing gum or others)

A short version of this extruder is used as forming extruder. Cooked licorice from a batch cooker or Surface Scraped Heat Exchanger is pumped into the extruder. If necessary this extruder will be equipped with a vacuum installation for dehumidifying the cooked mass and infeed rollers

Due to the intermeshing screws this machine is self cleaning.

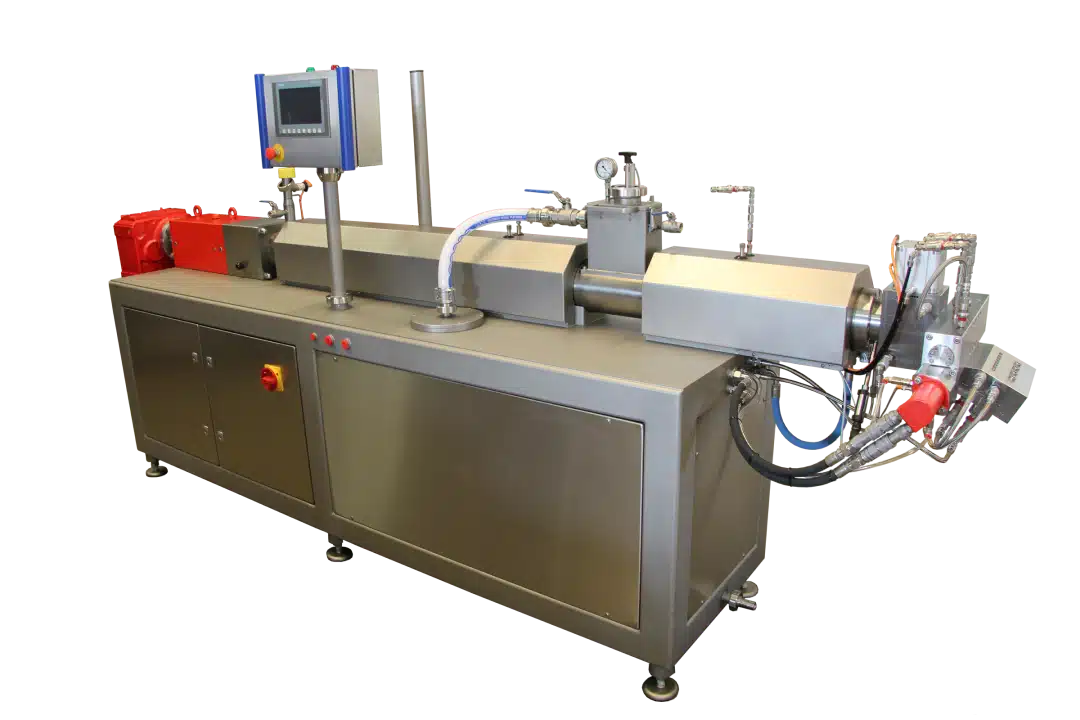

Form extruders

Also called “form press” is a twin screw, counter rotating, non intermeshing extruder. It’s sole purpose is to pump a viscous mass as sugar paste or chewing gum through a die system. Often this machine is equipped with infeed rollers.